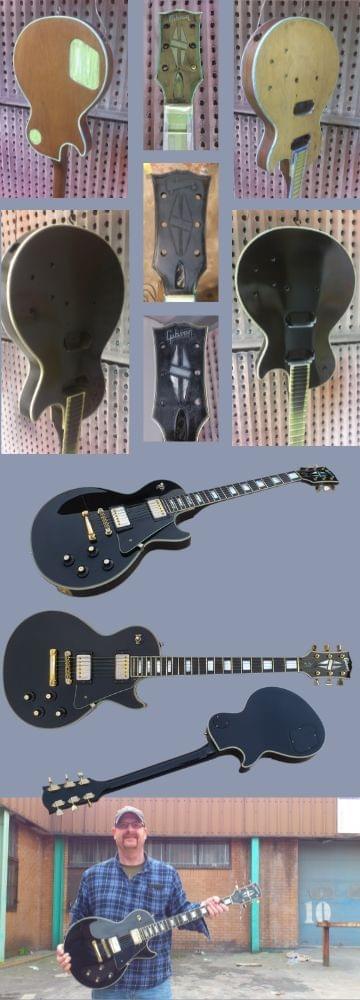

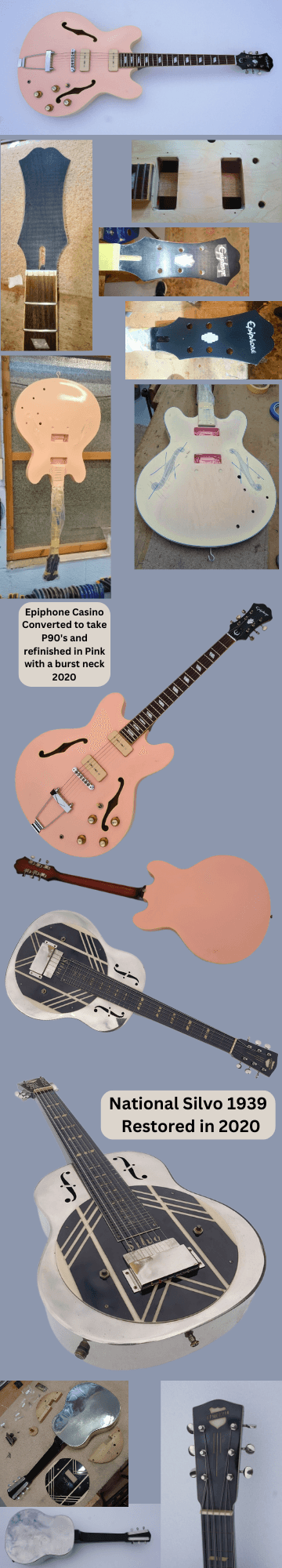

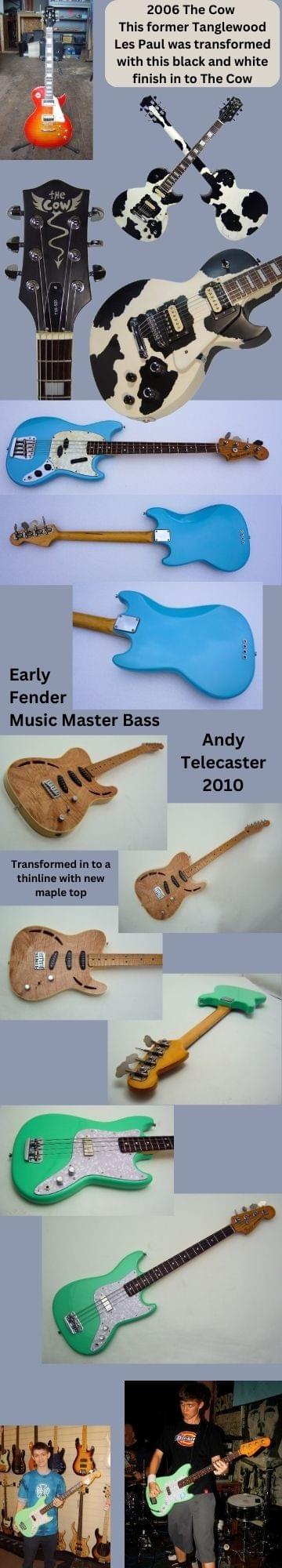

Master Instrument Maker and Repair Person

Bringing instruments back to life and creating dream guitars since 2002.

Master Instrument Maker and Repair Person

Bringing instruments back to life and creating dream guitars since 2002.

Spray Finishing

We produce the highest quality finishes avaliable for your instrument.

We are specialist finishers in:

Cellulose - Polyurathane - AC curing cellulose

Translucent Colours - Paint Bursts - Timber stains - Oils - Shellac - Waxes

Grain Fills - Grain Enhancement - Single Colour to Multi Colour Finishes

Metallic Flakes - Light Flip Paints - Paint Effects - Crackle Lacquer

Painted and Printed Artwork

Vintage Correct Finishes and Relicing Work

Popular Lacquers

The most popular lacquer we use is Nitrolocellulose, followed by our high gloss polyurathane for the ultimate high gloss finish that lasts!

Nitrocellulose and Cellulose

Cellulose lacquers are the second oldest version of paint that we use today to spray paint musical instruments. It is available in a wide range of glosses and types, we mainly use two types of cellulose, Natural Cellulose and Nitrocellulose. There are differences between the two and some applications suit one type over the other, although things can be done either way around.

Nitrocellulose is used for solid color instruments. Natural Cellulose and Nitrocellulose can be used for clear and translucent finishes, natural cellulose is a bit more flexible than the more modern Nitrocellulose that tends to crack as it crystallizes. Natural cellulose takes longer to dry than Nitrocellulose. Cellulose does not cure it only dries, this vintage style of finish will be susceptible to solvents and acids throughout its lifetime.

With Cellulose the best finishes are generally low lacquer finishes, high builds are more prone to checking and cracking if the paint build is done too fast. This is why people often sugest that cellulose is the best instrument lacquer, by the nature of the material most of the thinest finishes are found on cellolose instruments.

Bolt on neck bodies to replicate the vintage finishes can either be based in cellulose base coat or a polyurathane base coat - polyurathane provides a hard solid base to work upon that helps the top coat of nitrocellulose to be resistant to checking in the future.

Nitrocellulose and cellulose are available in glosses from 90% to 5% gloss and also in dead matte finish. 10-30% gloss polished gives the instrument a nice vintage shine.Time scales are very open-ended when we take on a cellulose finish as the build level will determine the drying time. If a perfectly flat finish needs to be achieved this can take extra time to achieve as the paint needs to fully harden before moving on to the next layers. Spray finishing work in cellulose is best completed during the warmer months to help with the drying times.

Cellulose Price List

Body of a Bolt on Neck Instrument

Bolt on neck bodies can either be finished in a full cellulose finish or mix mediums finishes.

The price of each job will be individually tailored to your instrument. Paint prices are based on removal of the old laquer and build up of the new laquer. If the instrument is in a ready to spray state then price will be reduced accordingly.

Time scales: After preperation of the instrument has been done, a minimum time scale of 4 weeks, generally we advise 6-8 weeks for spraying time

Full Cellulose Finish - Cellulose Base Coat, top coat either Cellulose or Nitrocellulose.

Thinnest finish body - This can either be clear, singular colour or translucent tint to the laquer, usually will have some paint dropping into the grain - from £260

Flat highly polished body finish, sutable for the application of all finishes, single colour, translucents, bursts and some paint effects from £320

Metallics, light flipping, pearlescents and many other paint effects - from £370

Hard Base layer with Nitrocellulose Top Coat - Totally Flat Finish Fast

The hard polyurathane base coat replicates dips and sprays sealing methods that have been used in the past. If you can get the base layer solid and flat faster then the colour and top coat can be applied much quicker. This base is generally used with Nitrocellulose for solid colours, bursts metallics and paint effects.

Body Polyurathane base, Nitrocellulose top coat flat thin finish from £300

This can either be clear, one colour or a translucent fiinish.

Body Polyurathane base, Nitrocellulose top coat flat finish for bursts metallics and paint effects - from £350

Necks of Bolt-on-Neck Instruments

Necks With maple and most bolt on necks timbers being of the close grain varieties of timber these only ususally require low lacquer builds a thinned out celulose base or schallec finishes are generally used before Cellulose or NitroCellulose top coat - from £170

Vintage yellow tints to translucents colours, bursts and grain enhansements - from £200

Neck and Body Refinishing of a Bolt-on-Neck instrument

Neck and body of a bolt-on neck full cellulose from - £420

Polyurathane base nitrocellulose top coat with a full cellulose neck from £370

Optional extra - painted headstock to match the body

Glue in Neck instruments

Full instrument form £460 Carved top instruments from £490

Bursts, metallics and other paint effects can be applied to a full instrument.

Extra options

Mix mediums finishes and differing glosses are not taken in to account in the price guide so feel free to ask about them, example - Painted body with waxed neck

Screening Paint for electrical cavities from £50

Decal fitting on headstocks from £70

Two Pack Cellulose Acid Catalysed Lacquer

A great alternative to the standard cellulose is this two-pack lacquer that is already used by several manufacturers in the music industry. AC or acid curing lacquer is a natural hard-wearing lacquer that uses a variation of cellulose lacquer as its base, now it is its own unique formulation. Acid cured lacquer is best used for faster finishing times in natural finishs that maintain its gloss and does not check or craze as much as standard cellulose. It does behave like normal cellulose sinking into the timber and checking over time yet this can take a longer time than standard cellulose.

AC Lacquer is a good choice for doing burst and paint effects it also is available in a wonderful special dead matt finish. The 90% gloss is very nice and this is my preferred lacquer to work with due to its ease of use, polishing attributions, off-the-gun finishes with low builds lacquers, it comes in a range of glosses 90% to 10% the dull lacquers polish up nice for a nice low gloss vintage look. It maintains a natural paint feel for the instrument and can be delivered in a range of different thicknesses of builds and is a very versatile paint to work with.

Acid Catalysed lacquer cures this means it is solvent resistant, it is still susceptible to acids with extreme fluctuations in temperature it can crack and check over time. It maintains its gloss without any further need for polishing and ages appropriately. This lacquer has been used in large amounts by the British instrument builders and acoustic makers so we have good records of how effective it has been.

Below are some of our options, with guide prices:

Bolt on neck instrumentsBody of a Bolt on Neck from £280

This can either be clear, singular colour or translucent tint to the laquer.

Body of a Bolt on Neck - Bursts - Metallics, Paint Effects - from £310

Necks of Bolt-on-Neck Instruments

Neck - from £120

Neck and Body Refinishing

Neck and Body of a bolt-on-neck from - £370

Glue in Neck instruments -

Full instrument from £400 Carved top instruments from £430

Bursts, metallics and other paint effects can be applied to a full instrument

Time scales, from 6 weeks, it is a chemically curing laquer that is cellulose based and does take a while to fully hardern. It may even gas off for a couple of months when new. It polishes very well to multiple sheens and mantaines its gloss very well over time.

Acid Cured Laquer is great for restoring and preservation work on guitars, with its range of glosses it is ideal for refretting work.

I find it to be one of the best laquers to work use with paint effects and metallics and other unusual finishes.

Polyurethane

Polyurethane is the highest gloss, hardest-wearing finish I produce, this is an excellent paint type that is fast-drying hard wearing and polishes up to the highest of all the glosses. It is the thickest of all the lacquers I use, if applied poorly it can be determental to the sound of the instrument. When done well then there is little to no difference between this and other finishes. Infact it can actually be thinner tthan other finishes whilst maintaining a durable and vibrant finish.

We focus on full gloss wet-look finishes for our polyurethane, so the best high shine finish avaliable that requires no maintenance other than a quick wipe. You can choose between a base coat of either thick - High Build Basecoat or thin - Polyurathane Sealer beneath the 100% gloss wet look laquer.

Our Polyurathane Lacquer has been specialy developed for the finishing of timber and has a self-leveling abilities that allow for low-builds levels of lacquer finishes.

Fully flat high gloss finishes are a job that I enjoy, polishing the instrument up to a perfect standard requires a lot of repeating steps to get up to a perfect scratch-free mirror-like finish. We specialise in wet look polyurathane and achieving the highest mirror finish gloss avaliable.

The paint that we work with is the wet-look variant, as it's 100% gloss is its main draw. Other glosses are avaliable, we feel it is better to offfer them in our other paint ranges.

Bolt on neck instrumentsBody - Bolt on Neck Instrument can either be undercoated with high build base coat or poly sealer. High build base is the fastest method for finishing musical instruments, this paint tends to turn a milky white if it sufffers damage where as the sealer stays a clear colour so we always recommend sealer for clear or translucent finishes and the high build base for solid colours. Polyurathane sealer is much thinner than high build base coat so it takes multiple coats to get to the same build level as one coat of high build base coat. Polyurathane Sealer is best for clears and translucent laquers, high build base works best for solid colours.

Polyurathane Finish - Body of a bolt on neck

Body of a Bolt on Neck High Build Base Coat - from £270

Body of a Bolt on Neck Polyurathane sealer - from £300

Body Drop in grain polyurathane sealer base, very fast super effective thin paint layers from £230

Body of a Bolt on Neck Metallics, Paint, Effects in addition to the build type from £40

Burst finishes are difficult in Polyurathane this effect really depends upon the colors used so please feel to get in touch to discuss.

Necks of Bolt-on-Neck Instruments

Neck - Poly Sealer and Wet Look top coat from £170

With maple and most bolt-on-necks timber being of a close grain timber variety solid base coats are generally not used on this type of neck.

Neck and Body Refinishing

Neck and Body High Build Bass Body Wet Look Top Coat from £420

Neck and Body Polyurathane Sealer Wet Look Top Coat from £450

Glue in Neck instruments - from £460

Carved top instruments from £500

Bursts - Metallics - Other paint effects from £460

Time scales from 2 weeks typically 4 week for fully flat finishes. Polyurathane is our fastest turn around paint finish to work with as it cures very quickley and can be re-coated the next day. To bring to a full mirror top does take a lot of polishing work so do expect to wait for the best quality work.

Other Finishes- techniques - Prints - Art Work

After two decades of restoring guitars I have tackeled about every type of paint work possible and am able to advice on the best course of action for you instrument.

Please get in touch about the kind of job you have with as much detail as possible and we will advise you on the course of action to take and costs involved.

We are always looking into new finishing techniques and have always been at the forfrount of progress with finishes. If you can not find what you are looking for on our price list then please get in touch.

Image printing

I am now able to offer image printing on musical instruments, both on the surface of the finish/under the finish to protect the image and on the plastic parts, have your favorite artwork printed in high quality on your musical instrument, I think this will be extremely popular with artists and customers alike as it will give them the able to print, album covers, artwork, or anything you would like on to their instrument.

The printer is not limited to printing on a flat surface it is capable of printing round corners, armrests and the contours of carved and shaped tops, we will need to experiment with the process for carved tops if a full top is to be printed as this is something we are yet to do. Small prints are very possible and achievable at this stage whilst we are still learning.

There are limitations on colors as it can only print in colour so gold, silver or copper hues are unavailable, only the shades of these element colours are available.

You are guaranteed the exact image you have selected, you do need to be careful that the image quality is high enough for this process to be successful, so it may be the case that we have to refuse to print your image if the image provided is not of a high enough quality. We will advise you during the process about the image quality and any scaling issues that may occur when it comes to spacing and positioning the art work.

It works out at a very good price over hiring an airbrush artist. Airbrushing is incredibly labour intensive and requires a very high level of skill to get a good image created and even then it is the artist's interpretation of the image where as this is an exact print of the art work provided. Please be aware that I hold airbrush artists and all spray artists work with high regard, as they provide incredible work.

We do hope to one day include in our range of services airbrush finishing work. I am very happy to spray templated work although free hand air brush is a bit too much for myself, hopefully as we expand I can introduce an artist in to the company.

Contact Us

Feel free to get in touch with your details, whether it be a repair, build or question, we'll get back to you to shortly to discuss your requirements.

Philip Porter Guitars © 2024